Aim for customers satisfaction with quality improvements and environmental management systems.

QUALITY MANAGEMENTN

- HOME

- QA / QC

- QUALITY MANAGEMENTN

RASIED ACCESS FLOORS

Quality Policy

Build a mutually profitable relationship with our customers, ensuring their long-term success, through the understanding of their needs and the needs of their customers as well.

Achieve our commitments for quality, cost, and schedule.

Develop staff competencies, creativity, empowerment and accountability through appropriate development programs and show strong management involvement and commitment.

Environmental Policy

Our longstanding commitment to environmental management and employee safety.

Our aim remains to conduct our operations in an environmentally responsible manner,

and maintain work environments that enable our employees to work in an injury-free environment.

QC Standards

Testing to the requirements of DIN 12825, JIS 1450 and CISCA Standards.

Test panels and pedestals from specific production runs to improve quality control procedures.

Detailed laboratory Inspection including the following tests based on individual customer's requirements.

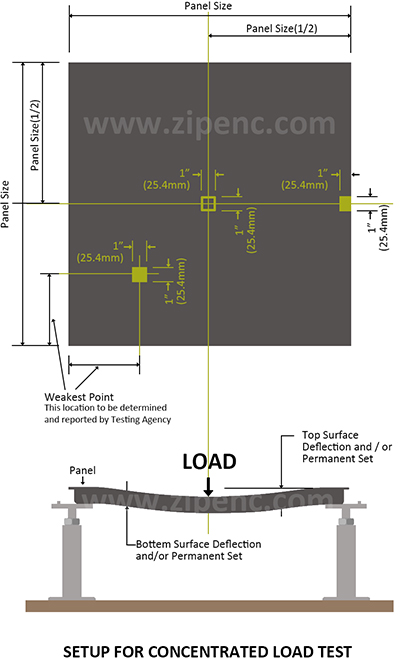

Concentrated Load Test

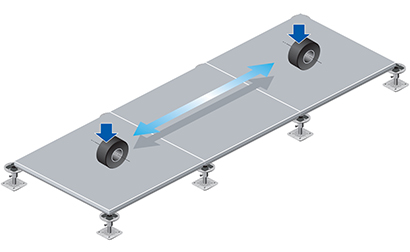

Concentrated Load Test Rolling load Test

Rolling load Test Impact Load Test

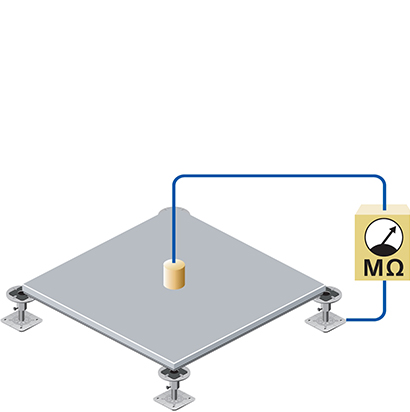

Impact Load Test ESD Test

ESD Test

Loading Test Method

-

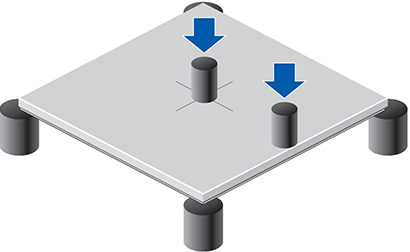

Concentrated Load

- Purpose : To determine the maximum

deflection(s) and permanent set(s)

of an access floor under load. - Maximum deflection : 2mm

- Purpose : To determine the maximum

-

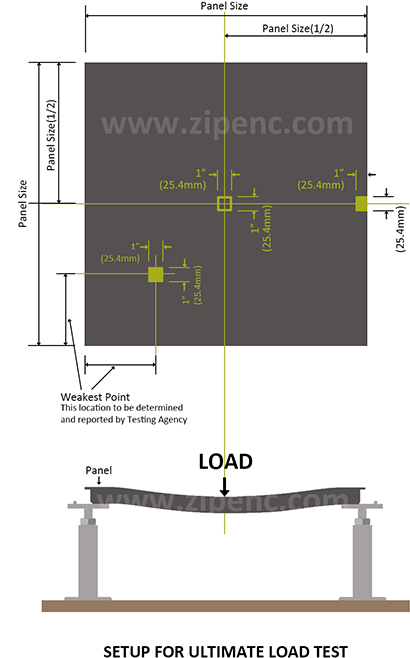

Ultimate Load

- Purpose :To verify the ability of an access floor to accept the manufacturers’ published ultimate load.

- Maximum deflection: point of failure

-

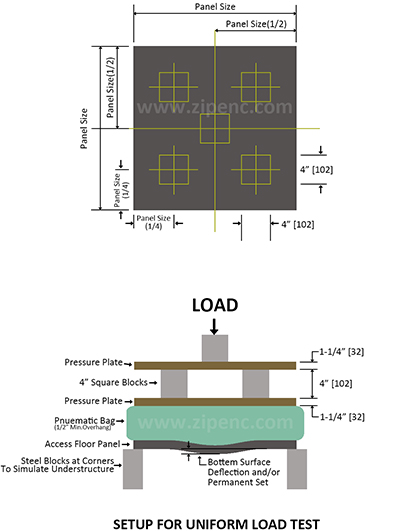

Uniform Load Test

- Purpose :To determine the maximum

deflection(s) and permanent set(s)

of an access floor under a uniformly

distributed load. - Maximum deflection : 2mm

- Purpose :To determine the maximum

-

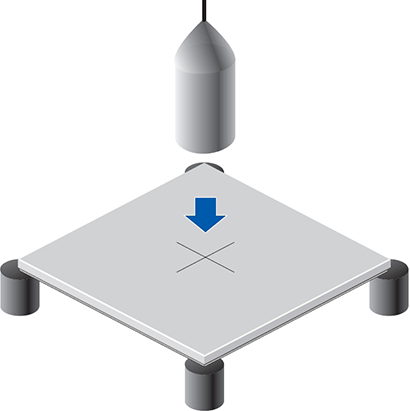

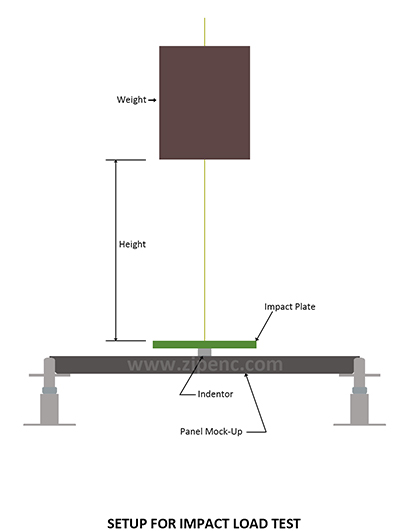

Drop Impact Load Test

- Purpose : The purpose of this test is to show the effect upon access floor panels and supporting understructure system(s) when subject to impact from heavy loads being accidentally dropped onto the floor panel.

- Maximum deflection: point of failure

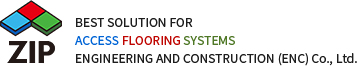

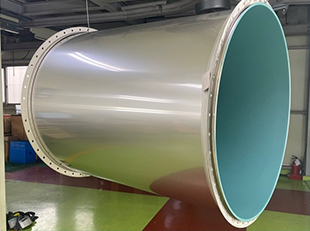

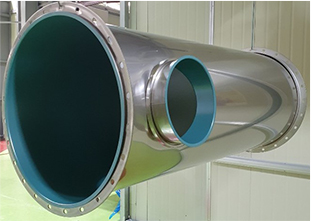

PERMASHIELD PIPE (PSP DUCT)

Quality Control

-

Materials Order

-

Product Shipment

Appearance inspectionInspection of dimensions, coating surfaces, scratches, etc.

Coating thickness inspectionBased on the thickness of the coating by partner

Discharge inspectionPinhole inspection at voltages above 2,500V

Shipment

Inspection -

Carrying into Field

Coating thickness inspectionBased on the thickness of the coating by partner

Discharge inspectionPinhole inspection at voltages above 2,500V

Carry-in

Inspection -

Product Conveyence

-

Operator Authentication

Installing on-site

Construction Quality Control

Only those who have completed the coating duct installation training are allowed to handle coating ducts.