High quality and competitive cost with high-tech systems and technology improvement.

ADVANTAGES

- HOME

- TECHNOLOGY

- ADVANTAGES

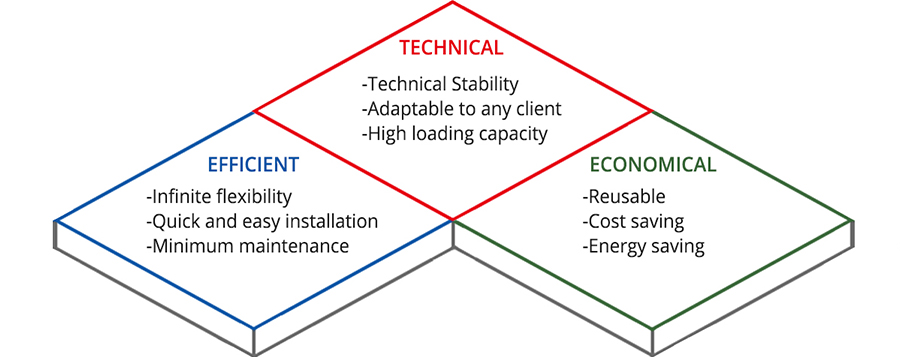

ADVANTAGES OF ZIP ENC's RAISED ACCESS FLOOR SYSTEMS

The use of ZIP ENC's access floor systems in the workplace in rapidly gaining popularity since they present a solution that is specifically designed to support information-rich and highly computerized business environments.

Owners and developers, along with building designers and facility managers, face the challenges of constantly changing space needs, technology-driven operations, high churn rates and the almost impossible task of maintaining flexibility while keeping life-cycle costs down. In fact, many traditionally designed facilities have been obsoleted due to wiring and wiring distribution problems created by organizational changes and advances in technology.

ZIP ENC's raised access floors minimize the initial impact on our plant and human health. Furthermore, the use of underfloor air distribution reduces energy use and provides advanced personal comfort control. Our raised access floor systems also improve the overall functionality of the building and our raised flooring system is independent and easily removable to allow access to the facilities underneath.

Installing ZIP ENC's raised access floor systems in your workplace allows for increased flexibility and brings with it a number of the following benefits.

- Power, energy, communication and data base systems can be housed in the plenum.

- Utilizing an underfloor air flow system provides energy efficient environmental control and improved air quality.

- Easy access to the building installations from any place at the raised access floor.

- Highest heavy-load capacity systems that allow haevy equipment to rest on without the need of benches of any other supporting tool.

- There are thousands of finish materials that can be used in ZIP ENC's raised access floor such as Deco, Carpet and ESD PVC tiles. This facilitates the possibilities of adaptation to the decoration and colors of the areas in which there are applied.

- The use of recycle materials and ZIP ENC's commitment with the environment has made of it worthy of Green building.

- Wiring, air conditioning equipment installation and the repairing service costs are reduced.

- The possibility of raising the system over a metre allows the levelling of the rooms at different heights.

- Reduce cable run lengths, eliminate cable trays which increased the aesthetic quality.

- It is a floor characterized by its durability and stability.

ADVANTAGES OF EQUIPMENT #1

- Secured advanced mechanical capability.

* 2250ton, 2500ton, 3500ton.

A more stable production capacity & Better quality

of die casting

High Pressure casting can be used by much more clamping force.

So, all our mold are designed based on the new mold to increase the pressure casting because loading capacity and entire product quality can be up and down depend on pressure casting. - Our die casting M/C are newly set up by Toshiba Japan These new M/C saved all the data from the pretesting and Mass production, So we can maintenance and improve product quality by the monitoring system.

ADVANTAGES OF EQUIPMENT #2

Modify the mold flow condition after flow injection

analysis.

Modify the gate shorten to improve the mold flow.

Upgrade the cooling device to keep the thermal

dissipation consistently.

For the best quality in mass production, we

basically use the Eject plate(C-clamp) to prevent

seizure burning.