ACCESSORIES

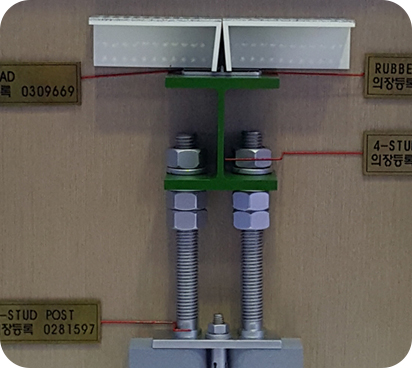

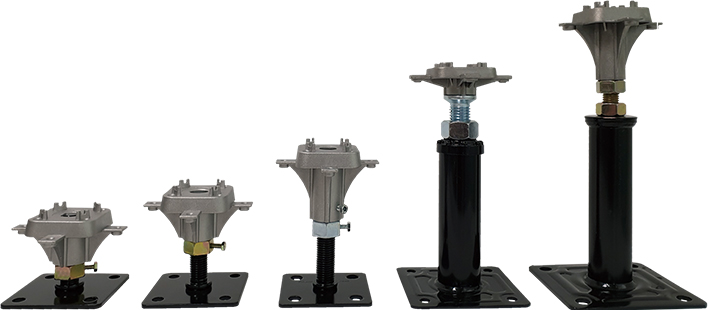

Pedestal Systems

Pedestal system is the complete vertical,adjustable supporting structure to the raised floor panels.

All pedestals incorporate the following features :- Compatible with solid, perforated and grating panels

- Pedestal available for all seismic environments.

- Finished floor heights from FFH100mm to FFH1,700mm.

- Pedestal system consists of base, tube, bolt, nut, head and cushion pad.

- Range of adjustment on normal pedestals is ±25mm

- Axial load : 3,000kgf ~ 11,800kgf

- Available with bare, e-coat or/and epoxy powder coat.

Aluminum Pedestals

Aluminum Pedestals Steel Pedestals

Steel Pedestals

Technical Information

| Material | Type | FFH (mm) | Dimension (mm) | Axial Load | Finish |

|---|---|---|---|---|---|

| All Aluminum |

S/D | 250 ~ 600 | 100(Base) + Ø33(Tube) + M25(Bolt) + One Nut + Al. Head | 4,300kgf (9,500lb) |

Aluminum Bare E-Coat Epoxy powder coat |

| H/D | 600 ~ 1000 | 150(Base) + Ø50.7(Tube) + M25(Bolt) + One Nut + Al. Head | 5,890kgf (13,000lbs) |

||

| Steel Base with Aluminum Head | L/D | 150 ~ 250 | 100(Steel Base) + M16(Steel Bolt) + One Nut + Al. Head | 7,700kgf (17,000lbs) |

Aluminum Bare E-Coat Epoxy powder coat |

| S/D | 150 ~ 600 | 150(Steel Base) + Ø33.1(Steel Tube) + M16~M20(Steel Bolt) + 1Nut + Al. Head | 9,500kgf (21,000lbs) |

||

| M/D | 600 ~ 800 | 150(Steel Base) + Ø48.6(Steel Tube) + M20~M24(Steel Bolt) + 1Nut + Al. Head | 9,920kgf (22,000lbs) |

||

| H/D | 800 ~ 1200 | 170(Steel Base) + Ø48.6(Steel Tube) + M22~M24(Steel Bolt) + 1Nut + Al. Head | 10,800kgf (24,000lbs) |

||

| E/D | 1200 ~ 1500 | 200(Steel Base) + Ø60.5(Steel Tube) + M24(Steel Bolt) + 1Nut + Al. Head | 11,800kgf (26,000lbs) |

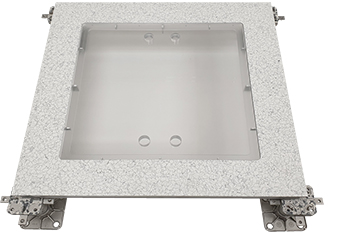

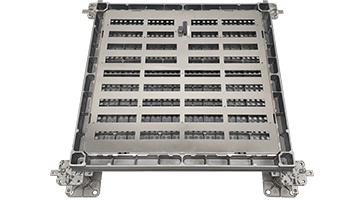

View Panel

Solid Panel can be fitted with and acrylic cover to enable quick and handy access to equipment devices located under the raised floor.

Aluminum Damper

Perforated and grating panels can be fitted with aluminum dampers. This unique damper system allows uniform balancing of air throughout the room or around workstations and manufacturing tools.

Close

Close Open

Open

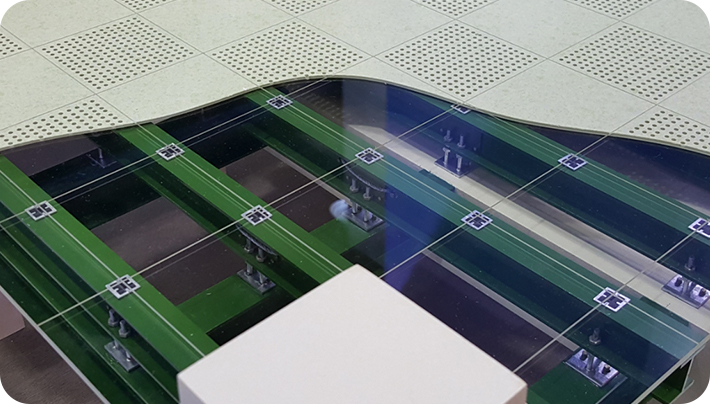

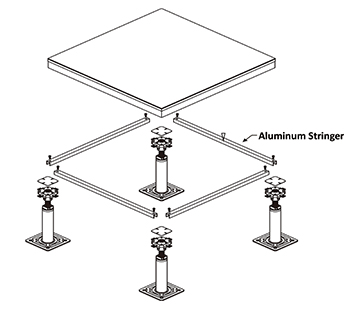

Stringers

Stringer is a horizontal component that connects pedestals together. It connects to the pedestal head and is used to provide additional lateral support at greater floor height and/or increase the structural performance of the raised floor system.

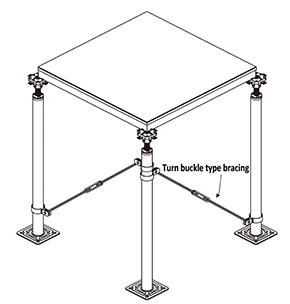

Bracings

This backing of the floor system is installed for heavily loaded areas such as tool move-in paths, heavy machine areas and seismic activity regions.

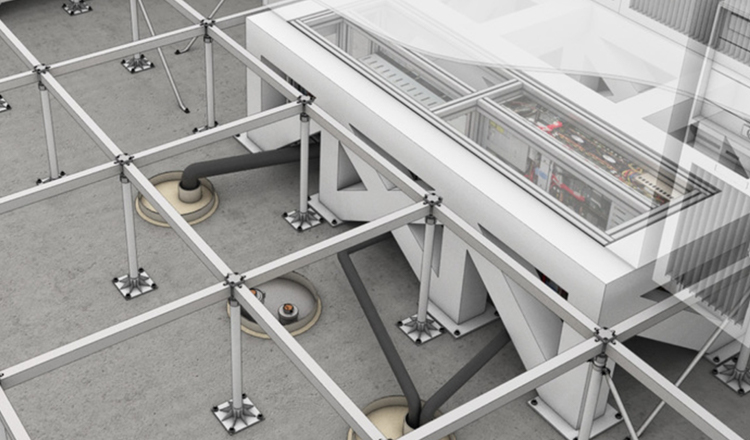

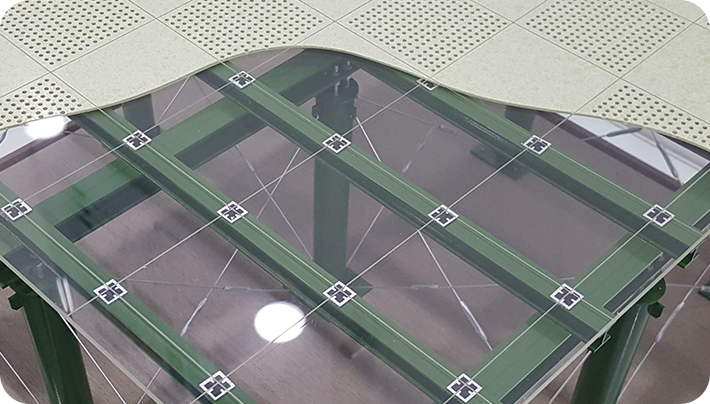

Post type understructure

This post type of understructure system is composed of main(upper side) and sub(lower side) beams and this type of structure system is the best solution for the limited area where wide span and space are required for the big size air ducts or other utility lines.

- Height range :

FFH 1,500 to 3,000mm - Available post pitch :

1,200 x 1,200mm

1,800 x 1,800mm

2,400 x 2,400mm - Adjustable within :

±25mm

Flat pad type understructure

With this particular flat pad type of understructure system are mainly installed on the top of the concrete waffle structure and The height is adjustable by using a bolt on the main(upper side) beam.

- Height range :

FFH 250 to 500mm - Available plate pitch :

600 x 1,200mm

600 x 1,800mm

600 x 3,000mm - Economical price

- Convenient installation